by janelle | Aug 25, 2014 | News

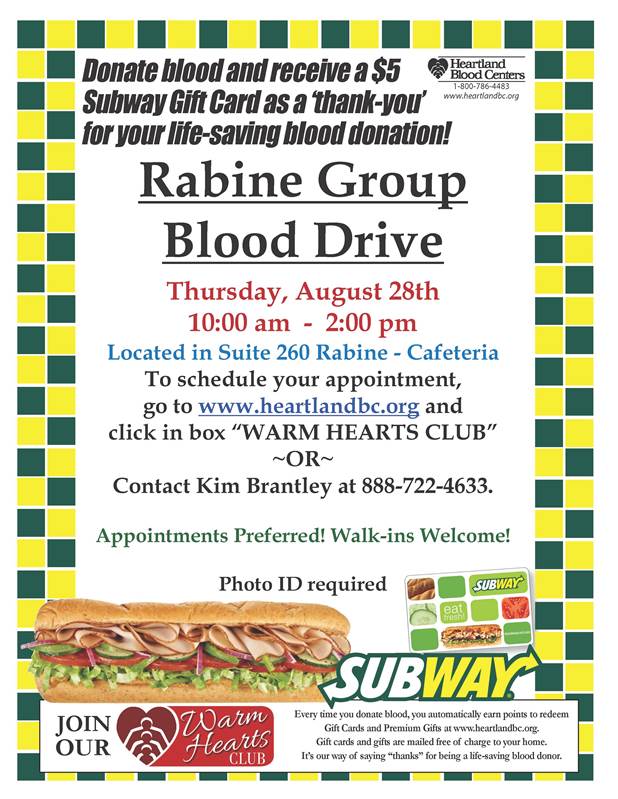

Rabine Group Blood Drive

On Thursday, August 28th, Rabine Group will be hosting a blood drive in the Cafeteria at our headquarters in Schaumburg, Illinois. All donors will receive a $5.00 gift card. Give the gift of life!

To become a donor, visit www.heartlandbc.org or contact Kim Brantley at (888) 722-4633.

by janelle | Apr 1, 2014 | News

April 1, 2014 –Schaumburg, Ill. and New York, NY– Rabine Group, the national leader in facilities management solutions, rang the closing bell for the NASDAQ Stock Market to commemorate its selection as a 2013 Chicago Innovation Awards winner among 10 honorees. The award recognizes Rabine Group’s dedication to world-class innovation through the introduction of a groundbreaking concrete flooring system.

The 2013 Chicago Innovation Awards honored Rabine Group for PrimeComposite a jointless concrete flooring system built for large industrial, cold storage and manufacturing facilities. The PrimeComposite flooring system can be poured for an area up to 65,000 square feet without a single joint, improving productivity for forklifts and eliminating maintenance created by traditional joints. Thinner slab construction requires less cement consumption and reduces the amount of C02 emissions by up to 30 percent, along with the amount of non-renewable resources otherwise needed.

“We are thrilled to be named a Chicago Innovation Awards winner for our PrimeComposite flooring solution. All of the NASDAQ listed companies are innovators in their own industries, so we are very honored to be here,” said Gary Rabine, CEO of the Rabine Group. “PrimeComposite is one example of how Rabine is ‘dematerializing’ the status quo with a concrete solution that harnesses science, technology and creativity and proves that less material can lead to more effective products.”

Accompanying the PrimeComposite flooring system, the team developed PrimeQuality SM to offer transparency into the concreting production process. This system provides real-time information, tracking and quality control as the product is made. Integrating PrimeComposite into building designs also contributes points to most projects qualifying for the U.S. Green Building Council’s LEED certification rating system.

In addition to ringing the closing bell, winners were invited to formally share their innovations with Chicago Mayor Rahm Emanuel and Illinois Governor Pat Quinn. All 10 honorees also received recognition at an awards ceremony and invitations to the prestigious Disney Institute’s innovation and training program.

“This annual event is an excellent example of how the Chicago Innovation Awards celebrates the spirit of innovation in organizations across all industries, sizes and sectors,” said

Tom Kuczmarski, co-founder of the Chicago Innovation Awards.

About The Rabine Group

Rabine is committed to delivering quality, innovation, and exceeding our clients’ expectations. Rabine Group is provider of pavement, roofing, snow removal, flooring, fuel, and other construction services. Rabine Group companies include: Rabine Paving, Rabine Paving America, Pavement Solutions, Crawford Roofing Experts, Rabine Snow Pros, Pipe View, and Rabine PrimeComposite as well as the Rabine Group Foundation.

by janelle | Mar 24, 2014 | News

Rabine Group Employees Shave Their Heads for Charity

Rabine Group Foundation is hosting a St. Baldrick’s Foundation event on April 29th, 2014 at the Rabine Group headquarters in Schaumburg, Illinois.

175,000 children are diagnosed with cancer each year. St. Baldrick’s is a charity which holds head-shaving events with the goal of raising money to fund research to help find cures for childhood cancer. St. Baldrick’s is dedicated to research, prevention, and early detection of childhood cancer.

Rabine Group employees have participated participated in past St. Baldrick’s events, shaving their heads in the name of charity. The Rabine Group Foundation is proud to continue supporting such an amazing cause.

To sign up to shave your head or to donate to the cause, visit www.stbaldricks.org/events/rabinegroupfoundation.

by janelle | Mar 12, 2014 | News

The snow is finally melting, revealing thousands of potholes left behind by the worst winter we’ve seen in years.

The Chicago Department of Transportation (CDOT) announced that as of March 2014, over 240,000 potholes have already been filled, with at least 25,000 potholes still tormenting drivers and pedestrians alike.

CDOT filled 625,000 potholes across Chicago in 2013, and it looks like they’ll have their work cut out for them this year. CDOT currently has 36 crews working to finish filling the currently reported potholes.

Potholes damage cars, present trip hazards and cause further deterioration to your pavement. For the safety of your patrons and to extend the life of your lot, it is vital to fill potholes and seal cracks immediately to prevent further pavement damage and to keep moisture out of the pavement. For more information on how you can extend the life of your pavement, contact us at (888) 722-4633.

by janelle | Mar 6, 2014 | News

Concrete’s Rock Solid Prices are Winning the Battle for Millions of Square Feet in Parking Lots.

By: Gary Rabine

Asphalt prices increased by 400% between 2006 and 2009 and have continued to rise since. Asphalt prices will continue to rise because the material is dependent on oil. Asphalt requires annual maintenance and has a relatively short life span—usually about 12-16 years assuming the lot is maintained each year.

Commercial property managers and building owners have known that asphalt prices rise and that asphalt parking lots require maintenance for years. So why have asphalt parking lots dominated the capital paving projects for so long?

The first reason is data. As more data about the true cost of maintaining an asphalt parking lot has become available over the last ten years, property managers and building owners are becoming more sophisticated in the way they evaluate capital spend and it’s impact on the ensuing maintenance of the lot. Second, the construction industry has made critical improvements to the equipment used in the placement of concrete. Finally, The Rabine Group invented UltraLot® Whitetopping giving property managers and building owners the option to convert an asphalt lot to a concrete lot at a lower cost than a full concrete replacement.

Pavement companies with national scale are relatively new and organizations like the Rabine Group have dramatically improved the industry’s ability to use data to forecast price increases and measure the cost of maintenance for asphalt lots. The standard methods of crack sealing, seal coating, striping, patching (removal and replacement), and asphalt overlays (resurfacing) will extend the life of an asphalt lot for an additional 5-10 years. However, these maintenance methods are subject to the same price increases as the initial asphalt parking lot! To make matters worse, the equipment required to maintain the asphalt consumes large amounts of oil and gas making the process even more sensitive to persistent oil price inflation. If any money is saved during the initial installation of an asphalt lot, those savings are undoubtedly lost during the maintenance phase of the asphalt parking lot’s life.

Unlike the oil dependent asphalt, the price of concrete placement has fallen due to advances in technology and the construction process. Concrete material by volume is less expensive than asphalt, but until recently, the process of pouring concrete has been much more costly. Equipment used to place asphalt has made dramatic improvements in accuracy, efficiency and accessibility—not to mention the implicit cost savings that a parking lot that lasts more than 40 years delivers to the bottom line. Concrete, on it’s own, has become more price competitive, sustainable and easier to work with while maintaining it’s integrity as a material that will last more than four decades.

It wasn’t until recently that concrete started replacing asphalt overlays in parking lots around the country. The catalyst for this shift is Rabine’s UltraLot® Whitetopping.

The UltraLot® Whitetopping process is similar to an asphalt overlay. The existing asphalt or concrete pavement must be ground down (milled) to the minimum thickness of the overlay application at all the areas of transition between existing asphalt and concrete pavements as well as drainage critical locations. The remaining existing pavement is ground to a minimum thickness, typically 1⁄4-inches to create a rough grooved surface for the concrete to bond when placed. If existing curb and gutter is not present, the perimeter edges must be framed and supported to define the limits of the whitetopping application. At this point, the parking lot is properly prepared and ready for concrete placement.

In years past, concrete parking lots would be poured using non-productive hand tools and truss screeds. While commercial concrete paving equipment has been on the market for over ten years, it is not until recently that technological advances in the form of 3D Laser Screeds have allowed it to be productively used on parking lots. 3D Laser Screeds allow for concrete to be placed quickly, accurately and at precise elevations to ensure proper drainage and construction. Upon completion of the UltraLot® Whitetopping, early-entry saws are utilized to cut control joints in a tight, controlled spacing pattern. By cutting joints in this configuration we provide the necessary flexibility in the completed surface for proper expansion and optimal pavement life over time. These advances in technology, combined with rising asphalt prices have made concrete paving and whitetopping a great option for parking lots.

For the first time, newly constructed concrete parking lots and whitetopping of existing lots are competing with new or overlayed asphalt parking lots. The real savings and value for concrete paving and whitetopping begins after the work is completed. The average lifecycle for a properly constructed asphalt parking lot is 12 to 16 years with normal annual parking lot maintenance. The average lifecycle for a newly constructed concrete parking lot is 30 to 50 years and a whitetopped concrete parking lot is 25 to 35 years. That is an average lifecycle increase of over 100%, not considering the reduced cost of maintenance overtime (no seal coating required) compared to a typical asphalt parking lot. Now that concrete and asphalt parking lot construction are comparably priced, serious consideration is being given to concrete options for any new parking lot construction or resurfacing project.

Engineers and architects very seldom design parking lots with concrete options for new construction and even less often for reconstruction and overlays. Make a practice of asking for concrete options when building or repaving a parking lot. If you struggle to get clear specifications feel free to call me, Gary Rabine, on my cell phone at (815) 693-9706. In the battle between concrete and asphalt, we only care that the customer wins.